The way appliances are made today barely resembles the factories of a decade ago. Things are moving fast, and Industry 4.0, sometimes called the fourth industrial revolution, is right at the center of it. For appliance makers, it’s no longer just about running traditional assembly lines. It’s about creating an environment where machines, people, and data actually work together. When sensors and connected systems feed real-time information into the process, problems are caught earlier, production moves faster, and quality doesn’t slip. SanHok, top home appliances assembly line and conveyor manufacturer, has seen how this shift is changing the daily reality for manufacturers. In simple terms, it’s about making appliances smarter, quicker, and with fewer headaches.

What Makes a Smart Factory Smart

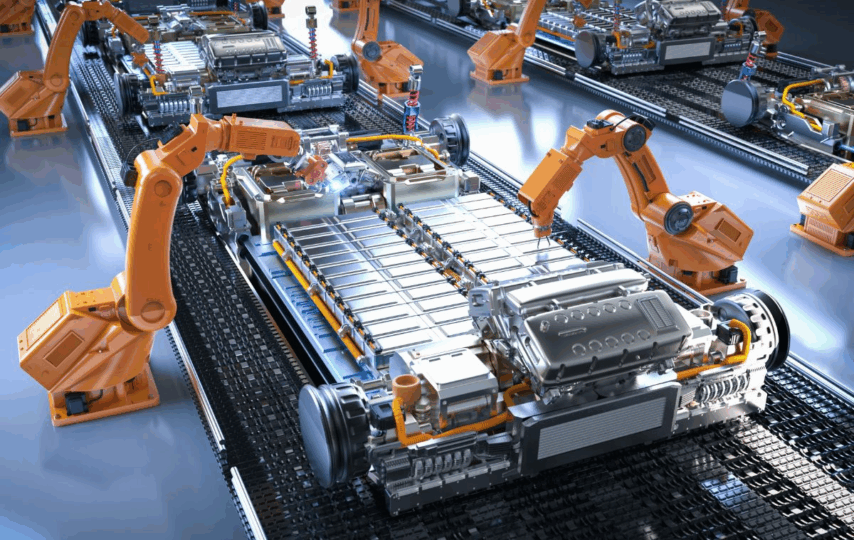

So what does a “smart” factory really mean? It’s not just robots or fancy machines. At its core, it’s a place where everything talks to each other. Small IoT sensors gather live data right from the shop floor. That data heads to the cloud, where analytics make sense of it and hand managers clear insights. Machines and digital systems are connected, almost like teammates constantly sharing feedback. Some factories even build digital twins, basically virtual copies of equipment, to test out changes before touching the real thing.

Put all that together and you get a factory that can bend instead of break when demand shifts. It can catch problems early, keep production steady, and move faster when needed. For appliance makers, that flexibility is everything. And here’s the thing: none of it works smoothly without conveyors, the systems that keep the floor moving. SanHok knows this better than most, having built conveyors designed specifically for this kind of smart setup.

Here’s Where Conveyors Come In

Think of conveyors as the arteries of a production line. Without them, everything clogs up. Sure, you can picture a belt carrying items from point A to point B, but in appliance factories they’re doing far more.

They bring parts to assembly stations at the exact right time. They move products past inspection points without delay. They carry finished goods to packaging so nothing stacks up waiting. All of this happens in rhythm, like music. And when that rhythm is broken, downtime creeps in. In short, conveyors don’t just move parts around, they keep the entire factory in sync. Without them, even the smartest systems would fall flat.

Meet the Smart Conveyor: The Unsung Hero

Here’s where things get interesting. Traditional conveyors just moved items. Smart conveyors think. They’ve got sensors built in, constantly tracking speed, weight, and flow. If something shifts, they adjust on the fly to keep production balanced. Energy-saving motors and advanced drive systems add more control, making movements smoother and more precise.

Flexibility is another big win. With modular designs, factories can reconfigure a line without tearing it apart. That matters when product designs change or orders spike. Remote monitoring is the cherry on top. Managers can check performance, catch hiccups, and fix issues without having to stand right next to the line.

Together, these upgrades make conveyors more like partners than passive tools. They cut waste, improve consistency, and help factories stay on track. SanHok has been working with manufacturers who rely on exactly these features to keep up with a competitive market.

Real Benefits: What You Actually Get

So what does all this mean in real life? For one, accuracy. Smart conveyors cut down on errors and keep quality in check. They also move products faster, from assembly to packaging, which helps companies meet demand without burning out the team.

Predictive maintenance is another big plus. Since the conveyors monitor themselves, they can flag an issue before it becomes a breakdown. Think of it like your car giving you a heads-up before the check-engine light ever turns on. That kind of warning saves money and prevents unwanted downtime.

There’s also the power bill. Modern conveyors run on efficient motors that use less energy, cutting costs and helping with sustainability goals. And let’s not forget data. With constant feedback, managers get a clearer picture of what’s happening on the floor, making it easier to spot patterns and make quick, confident calls.

Putting It All Together in Appliance Plants

When you step into an appliance plant, smart conveyors are the glue holding it all together. They move parts from assembly to testing to packaging, keeping things flowing without hiccups. At the same time, sensors feed data back into the system, which managers can act on right away.

Hook those conveyors up to a Manufacturing Execution System and things get even sharper. Managers can see exactly where each product is, find bottlenecks before they cause a slowdown, and adjust schedules without throwing the line off balance. Workflows adapt on the fly, which means factories can handle changes in demand or production without major setbacks. For appliance makers, that translates into higher efficiency, consistent output, and products that reach customers on time.

Start Your Own Smart Conveyor Makeover

Here’s the good news: upgrading doesn’t need to be overwhelming. The smartest move is to start small. Pick one line and try out a modular or IIoT-ready conveyor system. These systems grow with you. You can add sections, rearrange them, or scale up as demand increases. Adding a few sensors from the start can already give you valuable data about flow and wear.

Pair that with a simple data platform and you’ll start to see patterns in how the line runs. Over time, you can expand and connect more of your plant. Many companies have gone this route, beginning with a pilot and eventually running fully connected systems. SanHok has seen clients take this step-by-step path and end up with far more efficient factories without the stress of a massive overhaul.

The Future Is Moving Right Along with Smart Conveyors

Industry 4.0 isn’t a future buzzword. It’s happening right now, and smart conveyors are one of the clearest signs of that. They bring real, practical changes that cut downtime, raise quality, and help factories keep pace with growing demand.

For appliance makers, the choice is simple. To stay competitive, smart conveyors are no longer a nice-to-have, they’re a must. As factories evolve, conveyors will continue to play a central role, carrying parts, data, and progress itself forward. The factories of tomorrow depend on decisions made today, and SanHok is already helping build the systems that make that future possible.